search

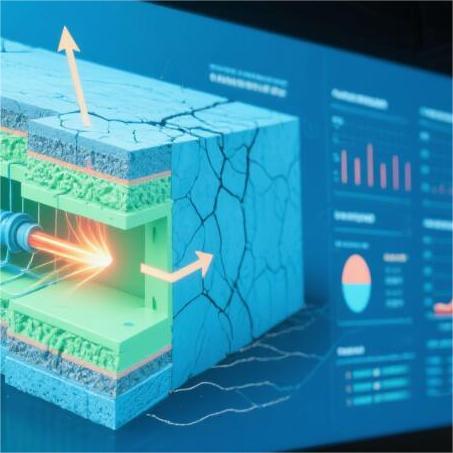

Concrete plays a pivotal role in defining the strength and longevity of construction projects. However, one significant challenge in large-scale projects is managing the heat generated during the concrete curing process. This is where a concrete cooling system becomes indispensable. By ensuring that concrete cures at an optimal temperature, construction teams can prevent cracks, structural weaknesses, and long-term damage, while achieving durability and high performance.

From building monumental dams to power plants and high-rise infrastructure, industries leverage advanced concrete cooling methods to meet complex demands. In this guide, we’ll explore why concrete cooling is essential, delve into the most effective methods available, and discuss how you can choose the best solution for your project.

Concrete is made up of cement, water, and aggregates, which chemically bond during the hydration process to form a hardened structure. This reaction is exothermic, meaning it generates significant heat, especially in large pours or hot environments.

When the temperature during curing rises above optimal levels, several issues arise:

Cracking: Excessive heat causes uneven expansion and contraction, leading to cracks that compromise the structure's integrity.

Strength Loss: High temperatures can reduce the final strength of concrete by accelerating hydration too quickly.

Thermal Stress: These stresses occur when different sections of the concrete structure cool at varying rates.

A concrete cooling system effectively alleviates these concerns by controlling the temperature during mixing, pouring, and curing, making it a critical tool for large-scale or hot-climate construction projects.

To achieve optimal results, construction teams can choose from a variety of concrete cooling methods, depending on the project’s scale, location, and requirements. Let’s break down some of the most popular options:

One of the simplest and most effective solutions, this method uses crushed ice or flake ice as part of the concrete mix. The ice absorbs the heat generated during hydration, lowering the temperature effectively.

When to Use: Ideal for medium to large-scale projects in warm climates.

Benefits: Affordable and straightforward to implement with commonly available materials.

This method uses chilled water to mix with concrete instead of regular water. Concrete water chillers cool water to near-freezing temperatures and circulate it into the batch mixers.

Advantages:

Greater precision and consistency in controlling temperatures.

Energy-efficient and scalable for continuous operations.

Best For: Projects requiring a controlled and steady cooling solution.

Air cooling involves using cooling tunnels or ambient airflow systems to reduce the temperature of materials like aggregates before mixing. This prevents heat transfer during the mixing stage.

Applications: The Aggregate cooling system is suitable for large-scale projects requiring pre-mixed concrete storage.

Challenge: Limited by the ambient temperatures of the project site.

This advanced method injects liquid nitrogen directly into the concrete mix, cooling it almost instantly. It ensures uniform cooling and can handle extreme temperature requirements.

Why It’s Best for Mega Projects:

Non-invasive and quick cooling solution.

Ideal for handling large pours in scorching climates.

Considerations: Higher upfront costs but invaluable for mission-critical projects.

For smaller-scale projects, shade structures and insulated covers can shield raw materials and poured concrete from direct sunlight and excessive temperatures.

Benefits: Simple and inexpensive where smaller cooling adjustments are sufficient.

Limitations: Effectiveness is limited during very high temperatures or expansive pours.

A range of factors influence which cooling method is best for your construction project. Let’s examine the key considerations:

For a small foundation or driveway, ice-based cooling or shading methods may be sufficient. For massive dams, bridges, or power plant foundations, advanced methods like liquid nitrogen injection or water chilling units are necessary to manage thermal stresses.

In tropical or desert climates, where ambient temperatures can soar, robust cooling systems are critical. Water chilling units and liquid nitrogen injection often outperform simpler options in these challenging environments.

Upfront Costs: Ice cooling and shading are often the lowest-cost solutions.

Long-Term Savings: Advanced systems like water chilling and nitrogen systems, while initially expensive, can reduce repair costs by preventing damage.

Modern construction trends lean toward eco-friendly practices. Systems like water chilling units can be designed with energy-efficiency measures to align with green building standards.

So why invest in a concrete cooling system? Here are some of the undeniable benefits:

Enhanced Structure Longevity: Cooling strengthens concrete and reduces risks of cracks and defects, yielding long-lasting structures.

Compliance with Standards: High-quality curing ensures regulatory compliance in large-scale government or commercial projects.

Reduced Repair Costs: By minimizing structural issues from the start, repair and maintenance expenses drop significantly.

Increased Efficiency: Advanced cooling systems streamline the curing process, leading to faster and more efficient project completion.

At FS Engineering & Supply, we understand the critical role concrete cooling systems play in achieving the highest standards of construction excellence. Our solutions are tailored to your unique project needs, ranging from compact ice-based cooling to industry-leading liquid nitrogen systems.

Wide Range of Systems: From basic cooling units to custom-engineered solutions for large-scale projects.

Expert Support: Our team has decades of experience in construction cooling systems.

Sustainability Focus: We ensure our systems are energy-efficient and environmentally responsible.

Pro-Tip: Investing in the right concrete cooling method from the start can save millions in long-term costs. Explore how FS Engineering & Supply ensures durability and strength for your projects.

Concrete cooling is essential to ensuring strong, durable, and defect-free construction in large-scale or hot-weather projects. By understanding various cooling methods—ranging from ice cooling to advanced nitrogen injection—the right system can be chosen based on your specific needs.

FS Engineering & Supply is here to provide the expertise, tools, and support you need. Don’t compromise on the foundation of your project—opt for cutting-edge cooling systems that deliver results. Contact us now at fsescm.com and safeguard the future of your construction efforts!