search

Compressors are essential components in various industrial and refrigeration systems, each type offering unique advantages and limitations. This paper examines the characteristics of piston, centrifugal, and screw compressors, highlighting their strengths and weaknesses to aid in selection based on specific operational requirements.

Advantages

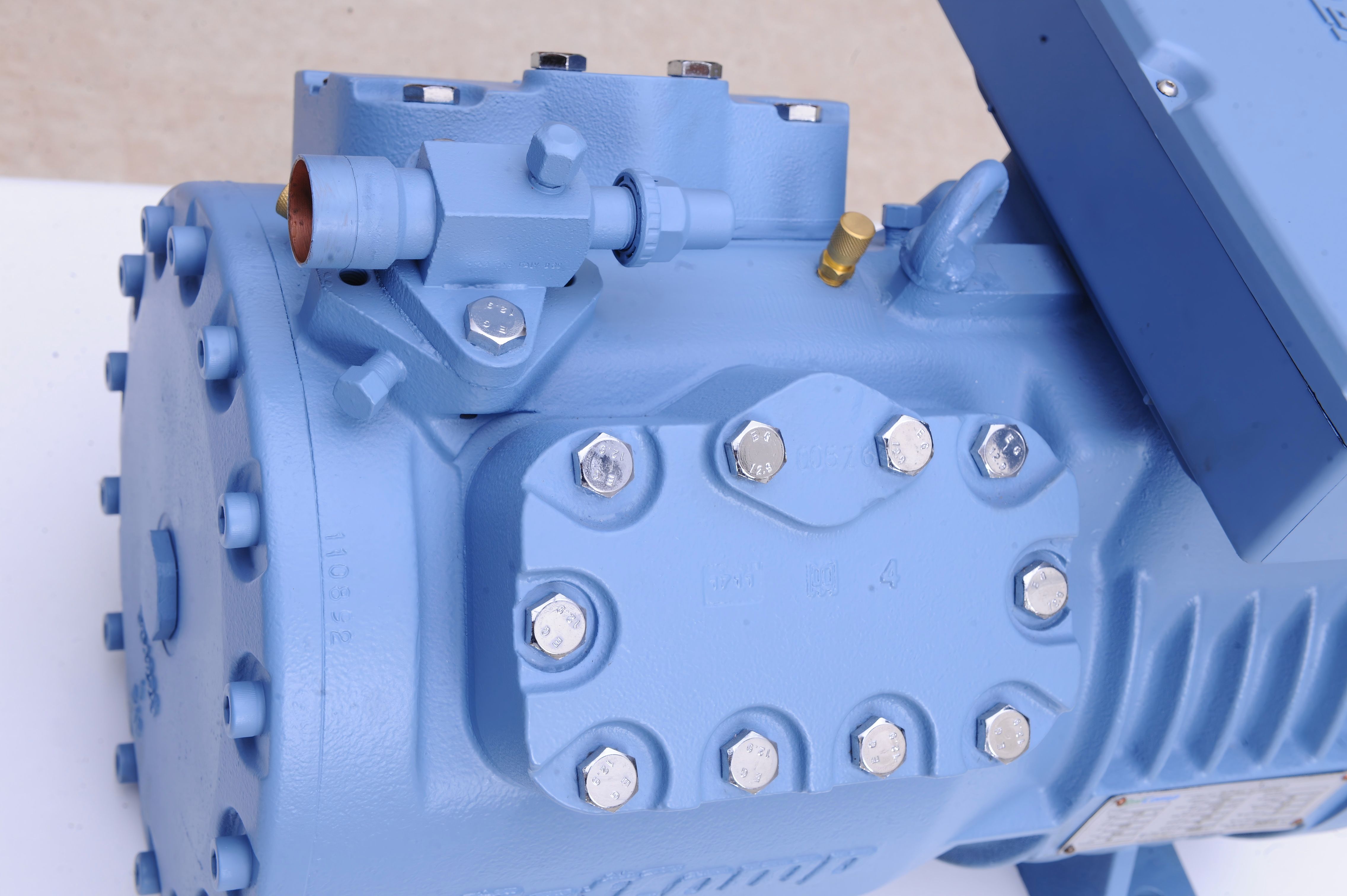

Piston compressors are widely recognized for their versatility and reliability. They boast a wide applicable pressure range, ensuring that the desired pressure is achieved regardless of flow rate. Their high thermal efficiency translates to lower power consumption, making them energy-efficient. Additionally, piston compressors exhibit strong adaptability, functioning effectively across a broad range of pressures and cooling capacities. They are easily repairable and constructed from low-cost materials, primarily ordinary steel, which simplifies manufacturing and reduces costs. With mature technology and a simple system configuration, piston compressors remain a popular choice in many applications.

Disadvantages

However, piston compressors have notable drawbacks. Their low rotational speed results in large and heavy machinery, limiting portability. The complex structure includes numerous vulnerable parts, leading to high maintenance efforts. The non-continuous exhaust creates air flow pulsation, and the machinery experiences significant vibration during operation, which can affect stability and lifespan.

Advantages

Centrifugal compressors are speed-based systems that excel in large-scale applications. They provide a uniform and pulse-free exhaust, ensuring smooth operation. Their high rotational speed enhances efficiency, and they operate with minimal internal lubrication needs, reducing maintenance. The excellent sealing minimizes leakage, and the flat performance curve allows for a wide operating range. Furthermore, centrifugal compressors are easy to automate and scale up, making them ideal for large industrial systems.

Disadvantages

On the downside, centrifugal compressors exhibit poor operational adaptability, as gas properties significantly affect performance. High air flow speeds cause friction losses, and the surge phenomenon poses severe risks to machinery durability. These limitations make them less suitable for applications with fluctuating loads or variable gas characteristics.

Advantages

Screw compressors combine the benefits of rotary and reciprocating systems without their respective shortcomings. They feature few components, leading to high reliability and low maintenance requirements. The absence of unbalanced inertial forces ensures smooth and vibration-free operation. Their forced gas discharge mechanism ensures consistent performance regardless of pressure variations, offering strong adaptability. Additionally, screw compressors are resistant to liquid impact and operate at low exhaust temperatures, even under high-pressure ratios. The infinite adjustment of cooling capacity (15%-100%) through slide valve mechanisms enhances energy efficiency and cost savings.

Disadvantages

Despite their advantages, screw compressors have certain limitations. The complex rotor surfaces require specialized, costly equipment for manufacturing, and the high noise levels can be disruptive. They are limited to medium and low-pressure applications due to internal clearance sealing and rely on a complex oil treatment system, increasing auxiliary equipment needs. In small volume ranges, screw compressors are less efficient compared to other types.

Each compressor type—piston, centrifugal, and screw—has its distinct advantages and challenges. Piston compressors are versatile and cost-effective but suffer from vibration and maintenance issues. Centrifugal compressors excel in large-scale applications but struggle with adaptability and surge risks. Screw compressors combine reliability and efficiency but face manufacturing complexity and noise concerns. Understanding these characteristics enables informed selection, optimizing performance and cost-effectiveness in industrial and refrigeration systems.