search

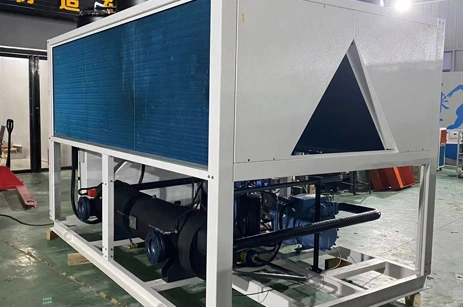

FSE's concrete water chillers are specifically designed for concrete cooling applications in extreme environments, ensuring reliable performance even at ambient temperatures as high as 45°C. These high-performing industrial water chillers provide chilled water within a precise temperature range of 1°C to 5°C, preventing thermal cracking and enhancing structural integrity in large-scale infrastructure projects. As one of the leading industrial water chiller manufacturers, FSE constructs its chillers with robust components designed to withstand harsh conditions, delivering stable cooling effects in challenging climates.

Maximize the performance of your concrete batch plant with FSE's advanced concrete water chillers. Designed specifically for concrete production, our water chillers ensure consistent temperature control, improving the strength and quality of concrete while reducing production delays caused by overheating.

FSE's innovative concrete water chiller systems are energy-efficient, durable, and easy to maintain, making them the ideal choice for high-demand concrete mixing environments. Whether you're managing a large commercial construction project or running a local batch plant, our water chillers optimize your operations by stabilizing concrete production processes even in extreme temperatures. FSE offers reliable, cost-effective cooling solutions that keep your facility running smoothly.

Water chillers in concrete cooling are used to lower the temperature of mixing water, ensuring optimal curing, preventing cracks, and improving the strength and durability of concrete in hot weather conditions.

An industrial water chiller is used for cooling machinery, processes, and equipment in industries like manufacturing, plastic injection molding, metalworking, food and beverage, chemical processing, and HVAC systems to maintain optimal performance and prevent overheating.

The function of an industrial water chiller is to remove heat from machinery, processes, or equipment by circulating chilled water, ensuring temperature control, preventing overheating, and improving operational efficiency across various industries.

An industrial water chiller works on the principle of heat absorption and transfer. It uses a refrigeration cycle where refrigerant absorbs heat from the water in an evaporator, reducing its temperature. The heated refrigerant is then compressed and passed through a condenser, dissipating heat into the surrounding environment. This cycle repeats to maintain water at a constant low temperature for industrial processes. Leading industrial water chiller manufacturers optimize this process for energy efficiency and performance.