search

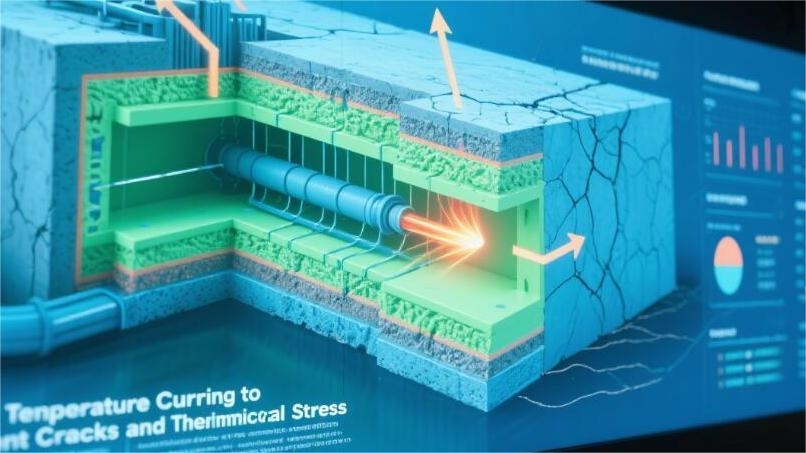

FSE's concrete cooling systems are specifically designed to reduce the concrete temperature in large-scale construction projects. These systems ensure optimal curing and maintain structural integrity throughout the construction process. Our solutions include three key equipment: water chiller, ice plant, and aggregate cooling systems. Each solution is carefully customized to meet the unique requirements of every project. By effectively lowering concrete temperatures, our cement cooling systems help prevent thermal cracking. They also ensure uniform strength development, which is essential for long-term durability. These features are particularly critical for large infrastructure projects such as dams, power plants, and other major constructions.

Comprehensive cooling solutions with aggregate and concrete cooling.

Efficient heat exchange for rapid temperature reduction.

Stable operation, ensuring smooth project construction.

Energy-saving design, reducing power costs.

Adaptable for tropical working conditions.

Large-scale infrastructure in hot climates

High-rise buildings

Hydropower dam & reservoir projects

Nuclear power plant projects

Precast concrete production

A concrete cooling system is essential for managing the heat generated during the concrete curing process, especially in large-scale or hot-climate construction projects. By implementing effective methods such as aggregate cooling systems and concrete water chillers, these systems prevent cracking, enhance structural durability, and ensure compliance with construction standards. Modern cooling systems not only improve concrete quality but also save costs by minimizing long-term repair needs. Explore innovative, energy-efficient cooling solutions tailored to your project with FS Engineering & Supply for reliable, high-performance results.

Also, visit Understanding Concrete Cooling Methods to learn more about concrete cooling.